Ghana Gold Mine Uptime Rescue Client

Objective

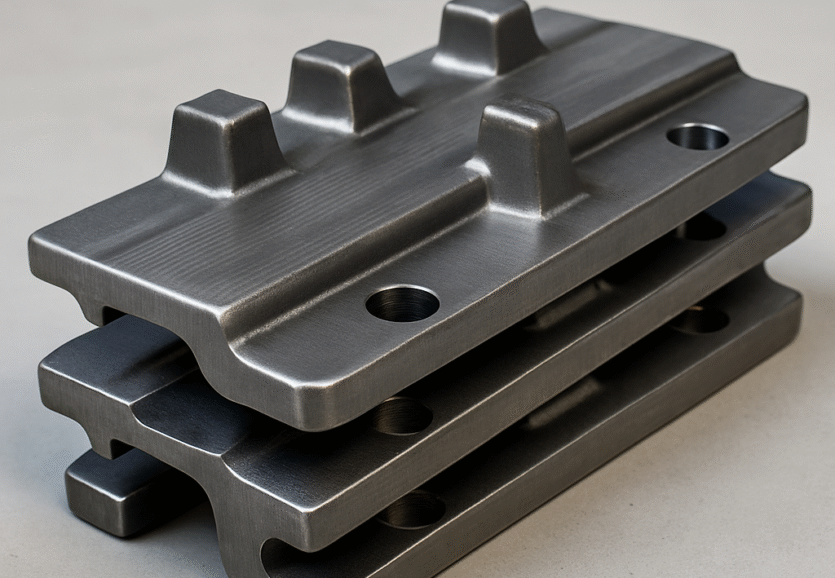

Slash weekly downtime caused by low-grade undercarriage shoes that wore out in just 50 hrs instead of 150 hrs.

Approach

-

Precision Parts Delivery

We supplied undercarriage shoes machined to ISO 10243 standards and prepped all BIS-style paperwork for fast customs clearance (under 48 hrs). -

Spare Kits & Guides

Each shipment included pins, rollers, and bolts. We held live video sessions to show how to remove old shoes safely, inspect mating surfaces, torque bolts correctly, and check track tension. -

Structured Rollout

Over four weeks, we assessed needs, delivered parts, supported on-site installations, and handed over detailed maintenance instructions.

Outcome

-

Downtime fell by 35% (from 10 hrs/week to 6.5 hrs/week)

-

Part life doubled from 150 hrs to over 300 hrs

-

Emergency repair costs dropped by 15%, saving roughly $22.5 K in month one