Background

In the heart of Ghana’s Ashanti region, a mid-sized gold mining operator was struggling with downtime that was dragging profits and morale. They ran a fleet of ten excavators day and night, digging through rock and soil to uncover gold-bearing ore. Every machine was vital: a single excavator offline meant slower production, missed targets, and mounting costs. Tough operating conditions and high loads pushed parts to their limits. When low-grade undercarriage shoes failed too quickly, the operator knew they needed a real fix and not just a quick patch.

The Challenge

Over a span of several months, the mine team saw each excavator halt for undercarriage shoe failures at least twice a week. Each breakdown cost them over five hours of downtime per machine. That added up to more than 10 hours of lost production every week for each excavator. At a rough estimate of $1,500 per hour for lost digging and crew costs, this meant about $15,000 lost per machine every week—$150,000 across the fleet.

Local suppliers offered replacement undercarriage shoes, but these wore out after just 50 working hours—far below the 150-hour lifespan they expected based on original equipment manufacturer (OEM) specs. Replacing them so often forced unplanned shutdowns, emergency repairs, and frantic parts runs across dusty back roads. The mine’s maintenance schedule was in chaos, fuel bills spiked from repeated idling, and teams worked overtime under stressful conditions.

Why Low-Grade Shoes Fail ?

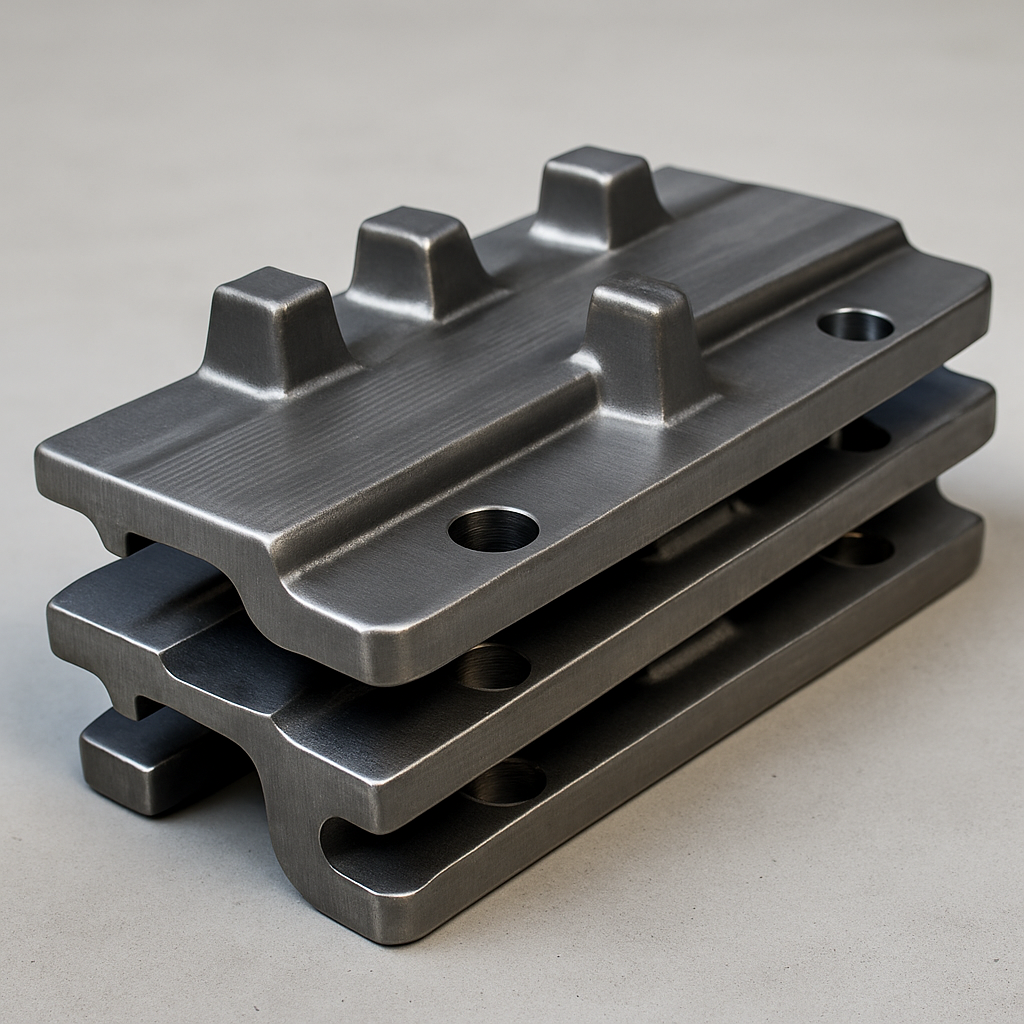

Undercarriage shoes link the excavator track chain to the ground. They must be tough enough to handle abrasive rocks and uneven terrain. The local parts were made of softer steel alloys that could not resist wear. Imagine dragging a fine-grit sandpaper over a rubber mat—it abrades quickly. In heavy mining, a shoe made from low-grade steel is like that sandpaper: it loses its shape and thickness fast, leading to metal-on-metal contact, track misalignment, and sudden breakdowns.

Over a full week, our field engineers guided the mine’s maintenance crew through every step of replacing undercarriage shoes. Each morning began with a video briefing where our lead engineer demonstrated how to remove the old shoes safely, using simple levers and pry bars. The team then learned to inspect mating surfaces for wear or damage, checking for scratches or gouges that could shorten part life. Next, we showed them how to torque bolts to the correct specification with a handheld torque wrench and verify track tension with basic measurements. Daily follow-up calls let us troubleshoot questions on the spot, and by week’s end, the crew was confidently managing replacements on their own.

At the same time, we followed a clear four-week rollout plan. In Week 1, we conducted an initial assessment via video call and finalized part orders. During Week 2, all ISO-certified undercarriage shoes cleared customs in under 48 hours and were delivered to the site. In Week 3, the team fitted new shoes on all ten excavators under our live support. Week 4 wrapped up with final pressure-test runs under full hydraulic load and the handover of detailed maintenance guides, ensuring sustained uptime and reliability.

Results

In the first month after fitting our ISO 10243-certified undercarriage shoes, downtime fell by 35 percent, dropping from an average of 10 hours per week per excavator to just 6.5 hours. Across the ten-machine fleet, that reclaimed 35 hours of digging every week, which works out to about $52,500 in regained productivity (at $1,500 per hour).

At the same time, shoe life more than doubled. Instead of wearing out after 50 operating hours, our precision-machined shoes ran for over 300 hours before showing any wear, 100 percent longer than the 150-hour OEM benchmark and 500 percent longer than the local copies.